|

In the previous chapter it was described how the Lambda sensor is integrated to the fuel injection system, and what influence it has on our bike.

There are so many rumors and theories on how the lambda sensor works and what it can do, so I decided to offer some more detailed information on the lambda sensor itself in a separate chapter.

The Lambda sensor is also known as an O2 sensor, but during this Book, I will only use the Lambda sensor term.

Measuring exhaust gasses.

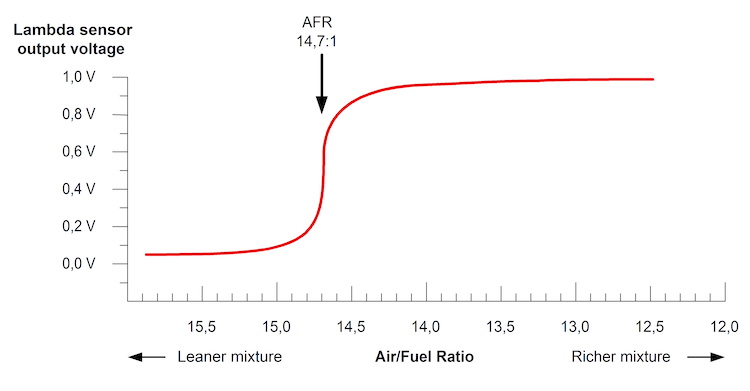

If you could produce a perfect combustion process, the fuel would consume all air molecules during the combustion and there would be no burnable fuel remains or any air molecules in the exhaust gasses. This would be the result if we could run the engine at the stoichiometric ideal AFR of 14,7:1.

The common narrow band output Lambda sensor that is used in all production motorcycles will search for air molecules in the exhaust and inform the ECU of a “Lean” condition if it detects air molecules in the exhaust.

The Lambda sensor is not very good at measuring the amount of air molecules in the exhaust, so it will basically switch its signal state within a very narrow AFR range when air molecules start to appear. (More or less like an on off switch)

The standard Lambda sensor is known as a “Narrow band Lambda sensor” due to its very fast shift in signal state.

It is important to understand that the lambda sensor will only detect excess air molecules, but can not see unburnt fuel molecules. So the Lambda sensor will have no clue what is going on when the mixture is getting richer – it will only react when the AFR is becoming borderline lean.

The Lambda sensor contains a heating element too, which seems a little weird considering that it is installed in the hot exhaust header pipe. But one of the problems with the lambda sensor is that its output characteristics will change with the temperature of the sensor, so the heater is included to heat up the sensor head as fast as possible.

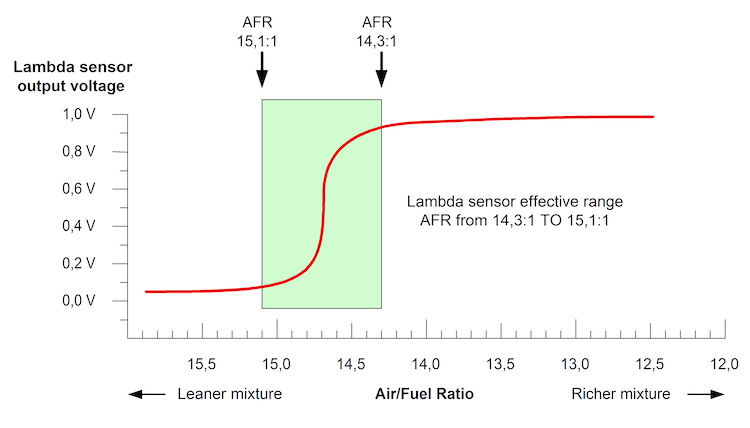

This fundamental behavior means that the narrow band lambda sensor has a well-defined operational range which is from around 14,3:1 to 15,1:1 (See the chart below)

To meet the emission requirements, the engine must be kept very close to an AFR of 14,4:1, which is close to the limit of the Lambda sensors effective range. But modern electronics and proper ECU programming makes it possible, and Closed loop operation where the Lambda sensor is keeping the AFR close to AFR 14,4:1 seems to work well on all bikes today.

But there is no way the narrow band Lambda sensor can be tweaked to adjust the closed loop AFR to a richer mixture, because it will have no clue what is going on when the AFR gets richer than aprox. 14,0:1.

The Wide Band Lambda Sensor

It only makes sense to talk about a narrow band sensor if there is also something called a wide band sensor – and there certainly is :-)

The wide band lambda sensor have a much wider operational range, and can cover any AFR you would want to run on your bike. It can be programmed to any AFR range you may desire, and is a great tool in racing and development, because it can tell you the exact AFR at any time.

Unfortunately, they are not for production bikes as they are expensive, fragile and needs frequent recalibration and they are not found on any production motorcycle.

Even if you were ready to pay the money for a wide band sensor and live with the frequent calibrations, you cannot just install a wideband sensor on your bike. The fuel injection ECU is preprogrammed to expect the input from a narrow band sensor, so it would not work. |

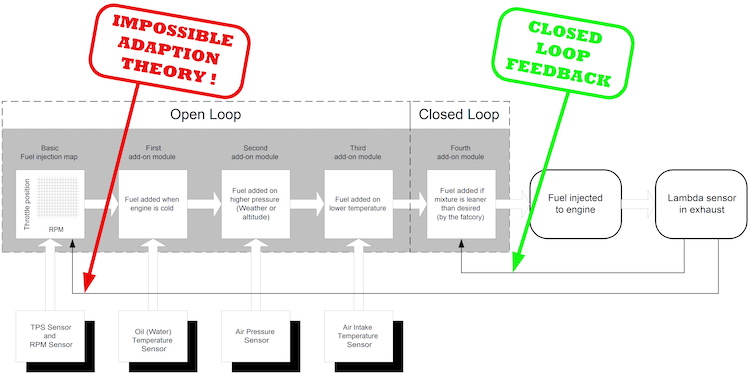

The map adaption theory.

As the Lambda sensor is giving feedback to the ECU, it is no wonder that there are discussions on what the feedback is used for.

It’s a common theory that the Lambda sensor feedback can be used to improve the basic fuel map. This is known as the adaption theory.

It would be nice if this was possible, because then the Lambda sensor feedback would be able to improve the fuel map which would benefit the open loop operation.

Unfortunately there is no way the narrow band sensor can accomplish this !

There’s a number of reasons why this can not work: - The Narrow band lambda sensor have a very digital (on/off like) output behavior that far from ideal for adaption.

- The very narrow operational range of the lambda sensor makes it impossible for the sensor to inform the ECU how much to adjust the AFR.

- The time delay in the sensor feedback require you to stay for a certain time in the same cell in the fuel map – which you only do in very few cells on the map.

If you were using the same fuel injection setup on a stationary engine with a constant speed and load, I’d say that it would be possible to let the lambda sensor adjust the map (because you would always be running the engine under the same conditions).

If you tried to do the same with the motorcycle engine you would see that a few cells would be updated, but you would never stay long enough in most of the over 200 cells in the fuel map to get them all done. This would just end up in a horrible uneven map, where you would actually destroy the original mapping.

We know that similar bikes from the production line are not running equally (too) lean from the factory – all due to the sensor tolerances discussed in a previous chapter (Actually the same tolerances that made the Lambda sensor necessary in the first place….)

If the adaption theory was correct and the ECU was able to update its own fuel map with input from the Lambda sensor, all bikes of the same type would end up with the same Air/Fuel Ratio over time. But a bike that is extremely lean from the factory does not correct itself, and a lucky owner of a bike that is running a tad richer than the rest will not see this advantage disappear over time.

The Lambda sensor will provide a real time fuel correction when you are riding in closed loop conditions, but this is just a final adjustment to the fuel injection calculations (The fourth add-on module).

There is no way the narrow band lambda sensor can provide information to update the fuel map in the ECU, and this means that the Open Loop fueling will stay as programmed by the factory.

The easy way to prove that the Lambda sensor can not update the fuel map: - If you look at the millions of motorcycles with aftermarket exhausts installed, you will see (hear) that most of them have some degree of backfire or popping in the exhaust when the rider close the throttle.

- The aftermarket exhaust will flow a bit more air than the stock exhaust, and more air means that the air/fuel ratio (AFR) changes to the lean side - which causes the backfire on deceleration.

- If the adaption theory was right, the lambda sensor would sense the change in AFR, and the ECU would update its basic fuel map - and then the problem would be solved and there would be no more popping or backfire in the exhaust.

- But we all know that these bikes does not cure themselves and the backfire stays the same over time - so there is no adaption process taking place !!!

|

| | | | | |  |